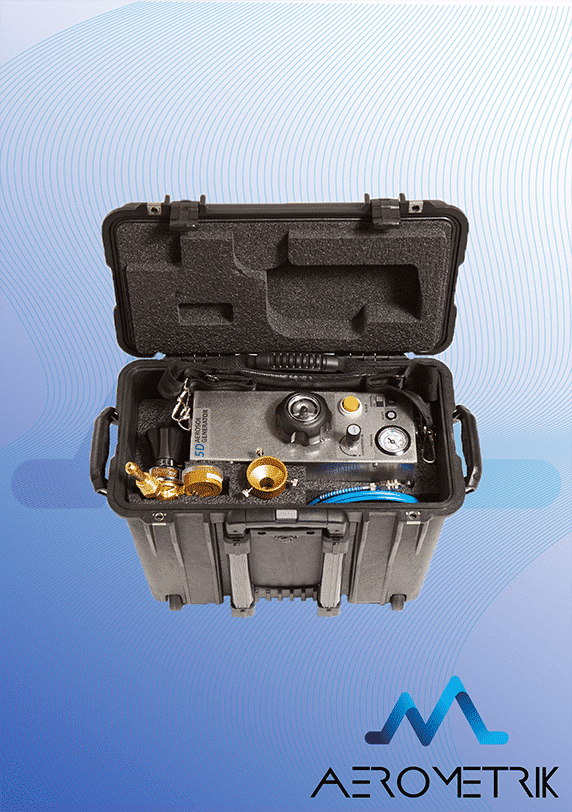

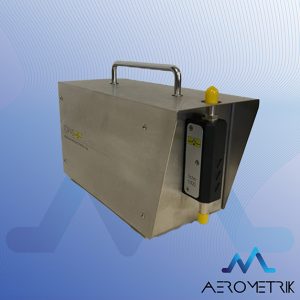

Thermal Aerosol Generator ATI Model TDA 5D

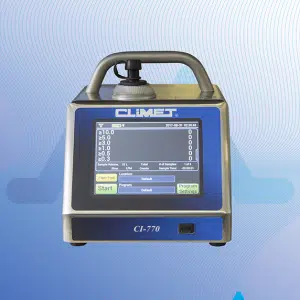

. Hepa Filter Testing ISO 14644-3.

. Fast operation with a warm-up time of only 60 seconds.

. Widest range of System Flow Rates 850 – 120.000 m3/hr.

. Rugged Portability.

. Safe and reliable Operation.

. Flex-Fuel Capacity.

. Lightweight and rugged, ideal for remote locations.

Features

Generating the widest aerosol concentration range available, the 5D accommodates both high- and low-flow environments, from cabinets1 to the most demanding cleanroom installations. And with flex-fuel capability, the 5D can use the following reagents, including DOP (DEHP), PAO-4, DOS (DEHS), Ondina, or mineral oil.2

1. Per NSF/ANSI 49, use 4B/4BL/6D laskin nozzle generators for biosafety cabinet testing.

2. Parrafin Oil and Corn Oil should not be used with a thermal generator.

Generation: Thermal vapor

Warm-Up and Cool-Down Time: 1-2 minutes

System Flow Rates: 833-119,000 m3/hr. (500 – 70,000 cfm)

Aerosol Output at Max Concentration: 100 µg/m3 @ 11,900m3/hr (100 µg/L @ 7,000 cfm)

10 µg/m3 @ 119,000 m3/hr (10 µg/L @ 70,000 cfm)

Max. Oil Consumption: 19.8 g/min (0.776 oz.)

Runtime: 41 minutes (at maximum oil consumption)

Particle Distribution: Meets ANSI/ASME N509/510

Flex-Fuel Capability: DOP, PAO-4, DOS, Ondina EL, and Mineral Oil

Standards: ISO 14644-3, CE RoHS 2 (2011/65/EU directive)

Size: 43 cm x 12 cm x 36 cm (17 in. x 5 in. x 15 in.)

Weight: 8 kg (approximately 17.6 lb) empty

Power: 120 VAC, 60 Hz, 10 Amps (for P/N 9300408 and 9300409)

240 VAC, 50 Hz, 5 Amps (for P/N 9300410 and 9300411)

Applications:

. Pharmaceutical Manufacturers

. Hospital operating theatres

. HVAC qualification companies

. Filter manufacturers

Accessories

. Heavy Duty Transport case with polyurethane wheels and a retractable handle allow for easy transport.

. Hose Adapter.

Associated services

. Equipment rental: available within 48 hours (depending availibilty). Full package including accessories, calibration certificate and consumable.

. Training session on site or in our office related to regulation, equipment use and data treatment .

. Calibration and metrological services are performed in our laboratory located at Betton (35).